ECO-innovative solutions in optimization processes of wastewater treatment

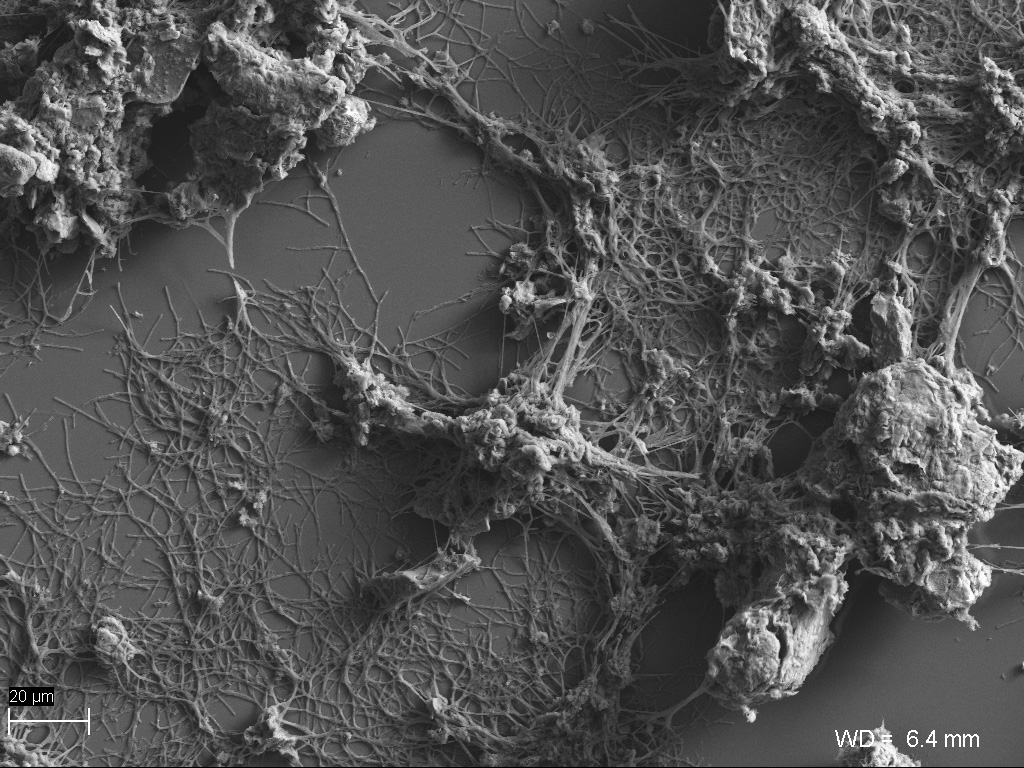

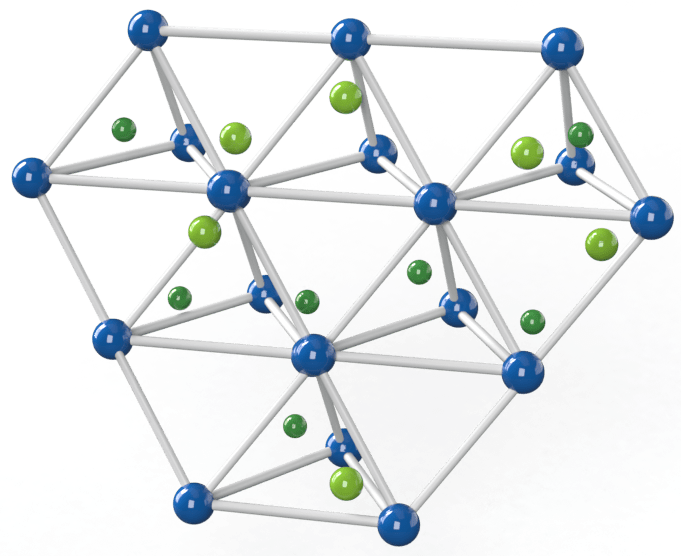

DuoBent is a technologically advanced group of aluminosilicate mixtures used in the optimization of both municipal and industrial wastewater treatment processes. Products are manufactured in accordance with a patented technology that ensures their safety.

Advantages of the DuoBent

DuoBent can be applicated at every stage of wastewater treatment, both in municipal and industrial treatment plants. Due to the modern formula, it provides improvement of technological parameters on many desired by wastewater treatment plants levels.

An animation explaining the process of how DuoBent preparations work.

Find out how our preparations work.

Check which DuoBent will solve your problems!

Below is a simple product configurator, which step by step, depending on the type of treatment, stage of treatment and problems, will indicate the appropriate DuoBent.

How to dose DuoBent?

DuoBent can be used at all stages of the wastewater treatment process. The dosing method is determined individually and depends on the application location within the wastewater treatment plant.

Dosing with the DuoFlow mixer

– Recommended

Dosing directly into the aeration chamber, minimizing the possibility of human error, which is often the cause of ineffective results

Manual dosing

– Optional, up to a maximum of 100 kg

There is an option for manual dosing directly into the aeration chamber, minimizing the possibility of human error. In this case, the product must be dosed very slowly and evenly, for example, using a paddle. The manual dosing time for one bag is 10 minutes.

Dosing using an automatic microdoser

– Individual option.

In cases where continuous dosing is necessary at high-capacity facilities, there is the option to install an automatic microdoser.

Suspension preparation system

– Customizable option

Liquids such as water, referred to as Newtonian fluids, have viscosity directly proportional to shear velocity. The colloidal suspension DuoBent, from a physical perspective, falls under the category of non-Newtonian fluids, meaning that the change in viscosity is not proportional to the shear velocity. In this case, viscosity changes depending on the shear velocity of the fluid.

To apply the fluid suspension DuoBent to raw wastewater, such as preliminary treatment or primary settling, it is possible to install a preparation system using hydro-monitors that enable the maintenance of homogeneity and dosing into the wastewater stream.